Packaging Solution Center

Testing & Automation in Action

Packaging Innovation Through Design, Testing, Optimization, and Monitoring

Our scientific, data-driven approach to packaging allows us to refine, standardize, and validate your packaging for transit to minimize product damage, environmental impact, and packaging spend.

ISTA-CERTIFIED TESTING

We simulate real-world transit conditions on state-of-the-art testing equipment to ensure product protection, minimize material usage, and reduce costs.

CUSTOM DESIGN & OPTIMIZATION

We work with our partners to design and sustainably optimize packaging that meets their unique business needs.

ENVIRONMENTAL TESTING

Determine how your product and packaging will react to varying temperature and humidity levels.

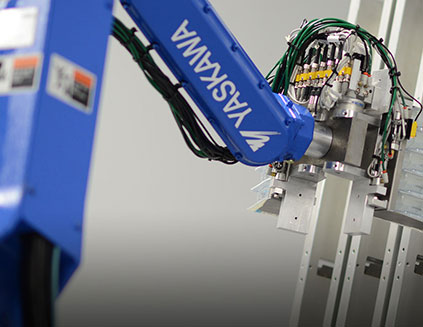

CUSTOM PACKAGING AUTOMATION

Custom automation installations provide your business with efficiency, accuracy, and cost savings.

E-COMMERCE

Using pack stations and automated fulfillment lines, we address many of the challenges facing the e-commerce industry today.

FILM LAB

Our testing equipment helps you find the optimal flexible packaging for your unique application.

STRETCH FILM CIRCULARITY

We are creating a closed loop for stretch film with our recycling equipment that creates high-quality PCR resin.

EDUCATION & TOURS

We train and educate our customers about the science behind load containment and conduct facility tours of the Packaging Solution Center.

ISTA CERTIFIED

Solution Center Videos

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Sub Heading

Our goal is to expose the science behind packaging to create proven solutions for our customers through simulating and measuring real-world transit dynamics. Load containment testing allows us to optimize your packaging to minimize product damage, material usage, and costs.

In addition to our testing capabilities, the Packaging Solution Center features an end-of-line packaging automation showroom, including e-commerce fulfillment equipment; our Packaging Research & Film Lab; our MUST: Stretch Film Management Program; and our custom packaging design team, factoring heavily in our mission to achieve more sustainable packaging.

WHAT WE OFFER

Testing, Design, & End-of-Line Automation

need help? Call us

(800) 722-5841

or

Featured Partners

“If one of our customers is experiencing damage in transit, we can recreate that specific route in our center to see where and how their products are failing. This allows us to create customized packaging solutions based on scientific data, virtually eliminating shipping damage and reducing overall packaging costs. ”

Kyle Pischel

Lead Engineer, Packaging Solution Center